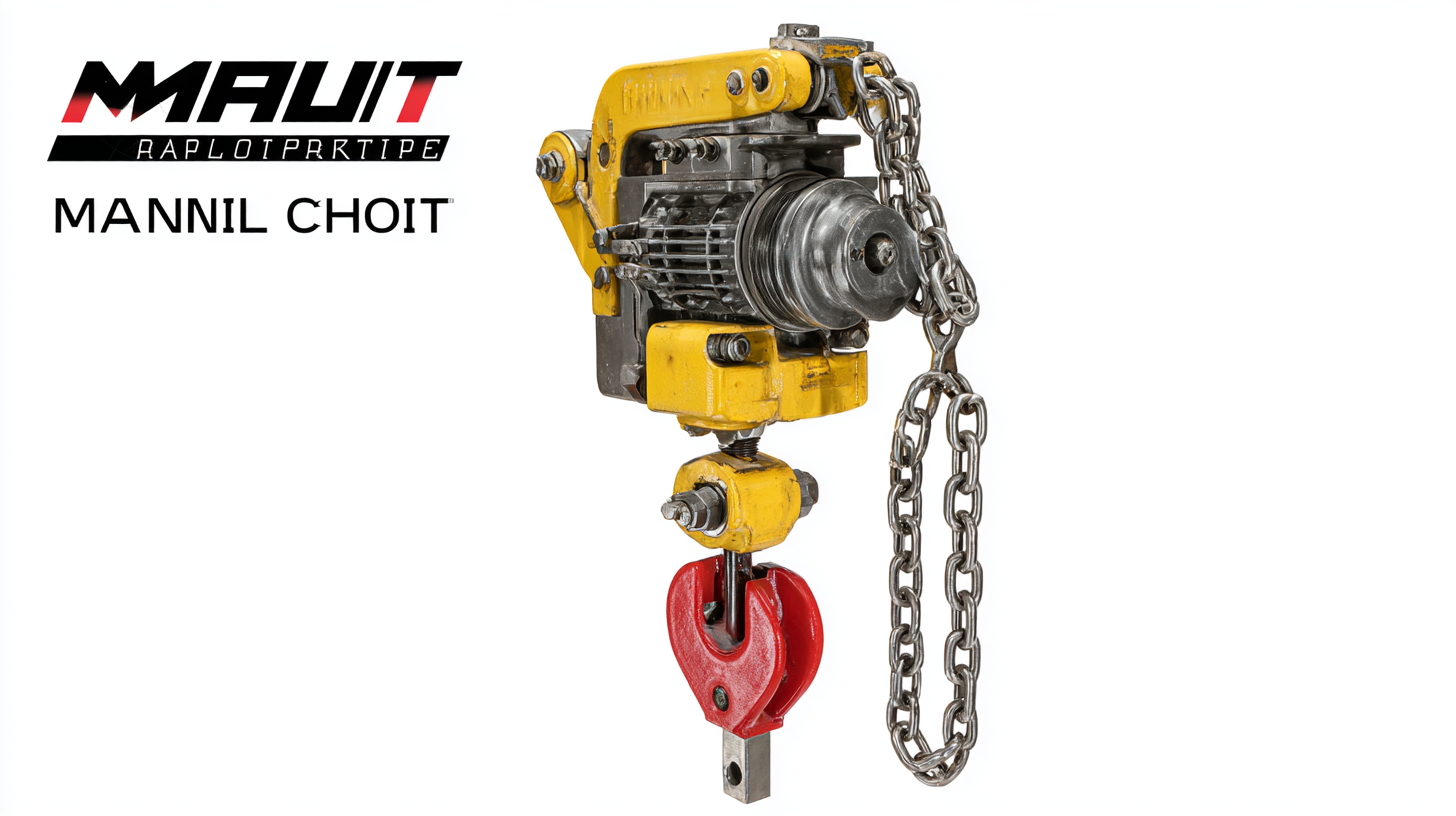

Innovative Applications of Best Manual Chain Hoists in Modern Industry

In the ever-evolving landscape of modern industry, the significance of Manual Chain Hoists cannot be overstated. These versatile lifting devices have become indispensable across various sectors, providing reliable solutions for material handling and heavy lifting tasks. As we explore the innovative applications of the best Manual Chain Hoists, we delve into how their unique designs and features continue to enhance operational efficiency and safety. Manufactured with precision and a keen understanding of industrial needs, these hoists exemplify excellence in craftsmanship, reflecting China's manufacturing prowess while catering to a global market. From construction sites to manufacturing plants, the integration of Manual Chain Hoists signifies a commitment to elevated productivity and streamlined processes, underpinning the very foundation of modern industrial practices.

Emerging Trends in Manual Chain Hoist Designs for Industrial Use

In recent years, the design of manual chain hoists has evolved significantly to meet the demands of modern industries. One prominent trend is the integration of lightweight materials that enhance portability without sacrificing strength. Advanced composites now play a role in construction, allowing for hoists that are not only easier to maneuver but also boast higher load capacities. These innovations open doors for their application in tight spaces and challenging environments where traditional hoists might fall short.

Another emerging trend is the incorporation of ergonomic features aimed at reducing user fatigue and enhancing safety. Modern manual chain hoists are being designed with adjustable handles, improved grips, and smoother operating mechanisms. Such advancements cater to the growing awareness of workplace health and safety, ensuring that operators can work more efficiently and with less strain. Moreover, manufacturers are increasingly focusing on compliance with international safety standards, reflecting a commitment to providing reliable equipment that prioritizes user protection in industrial settings.

Key Benefits of Manual Chain Hoists Over Electric Alternatives

In modern industry, manual chain hoists are gaining renewed attention as a practical alternative to electric hoists, primarily due to their simplicity and reliability. Research indicates that in various applications, manual chain hoists can outperform electric options, particularly in scenarios where power access is limited or where portability is crucial. For issues concerning sustainability, a study highlights the efficiency of manual solutions, revealing a lower carbon footprint associated with manual hoisting systems compared to electric counterparts, which often require extensive energy inputs and maintenance.

Moreover, the maintenance costs for manual chain hoists are significantly lower, with estimates suggesting they can save companies up to 30% in overall operational costs. This is particularly pertinent in industries like automotive manufacturing, where the lifecycle assessment of recycling options shows that simpler solutions often carry less environmental burden. As businesses strive for more sustainable practices, integrating manual chain hoists into their operations not only enhances efficiency but also aligns with eco-friendly goals. The evolving landscape of lifting technology emphasizes that sometimes, traditional tools can still deliver the most effective results.

Safety Innovations in Manual Chain Hoists for Enhanced Operation

Recent advancements in manual chain hoist technology have put a strong emphasis on safety innovations, crucial for enhancing operational efficiency in modern industries. Reports indicate that improper handling and equipment failure contribute to approximately 25% of workplace accidents in manufacturing settings. Innovations such as load-sensing technology and automatic braking systems are now common features in high-quality manual chain hoists, significantly reducing these risks. By integrating these safety mechanisms, companies can not only protect their workers but also enhance productivity through reliable equipment performance.

To maximize the benefits of manual chain hoists, it’s essential to follow best practices. Tip: Always conduct regular inspections and maintenance to ensure that hoists operate safely and efficiently. Furthermore, training personnel on the proper use of these devices is critical; statistics show that nearly 60% of accidents are linked to operator error. Tip: Implement a comprehensive training program that includes hands-on sessions paired with safety protocols. Emphasizing safety in the operational culture can lead to a substantial decrease in workplace incidents, ultimately supporting a safer and more productive environment.

Versatile Applications of Manual Chain Hoists Across Various Industries

Manual chain hoists have become indispensable tools across various industries, showcasing their versatility and effectiveness in lifting and moving heavy loads efficiently. According to a recent report from the Material Handling Industry of America, the manual hoist market is expected to grow by 5.2% annually, driven by the increasing demand for materials handling solutions in manufacturing, construction, and logistics sectors. These hoists offer a compact solution that does not require electricity, making them ideal for both indoor and outdoor applications, from warehouses to construction sites.

In the construction industry, for instance, manual chain hoists are crucial for lifting materials to great heights safely. A study by the International Labor Organization indicates that construction workers are often exposed to heavy lifting tasks, leading to an increase in workplace injuries. However, the use of manual chain hoists can minimize these risks, providing a safer alternative to traditional lifting methods. Additionally, in the manufacturing realm, these hoists facilitate assembly line operations, enabling smoother workflows and improved productivity. As industries continue to pursue efficiency and safety, the innovative applications of manual chain hoists will undoubtedly play a significant role in modern industrial practices.

Innovative Applications of Best Manual Chain Hoists in Modern Industry

This chart illustrates the versatile applications of manual chain hoists across various industries, highlighting their significance in logistics, construction, manufacturing, and entertainment sectors.

Comparative Analysis: Manual Chain Hoists vs. Other Lifting Solutions

In the realm of industrial lifting solutions, manual chain hoists remain a staple for many organizations, primarily due to their simplicity and effectiveness. When compared to electric hoists and hydraulic systems, manual chain hoists have distinct advantages. They are typically more affordable, require less maintenance, and can be used in environments where electrical power is inaccessible or unsafe. This makes them an ideal choice for smaller operations or temporary setups where frequent relocation is a consideration.

Moreover, the comparative analysis reveals that manual chain hoists offer superior control over lifting processes. Operators can handle loads at a steady pace, minimizing the risk of sudden drops that can occur with more automated systems. Additionally, their lightweight and portable design make them easy to maneuver in tight spaces, an essential factor in many manufacturing and construction scenarios. While electric and hydraulic hoists excel in speed and heavy lifting capabilities, manual chain hoists provide a reliable, cost-effective alternative that prioritizes safety and versatility in a variety of industrial applications.

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org